Gd&T Pattern Of Holes

Gd&T Pattern Of Holes - Do you want to reduce production costs? It can be used almost anywhere to represent any feature of size. This course will teach you the basics of how to understand gd&t symbols and their use. Web however, the basic concepts identified below provide a solid introduction to the topic, highlighting ways in which gd&t can be used to control fits of holes/shafts in order to provide additional control on the fit geometry. Web on the right, the pattern of four holes is a primary datum. Web quickly shows how to use gd&t to locate a simple clearance hole on a flat plate.instagram: Web a composite feature control frame (fcf) contains two tolerance zone frameworks. Web we often see a pattern of holes as an assembly feature on a part. Figure 1 shows a composite fcf controlling position tolerance of a pattern of holes. 6 x 60.00 deg (with an angular tolerance dependent on how you interpret the drawing) the location of the center of the bolt circle: The tolerance of position locates the holes within the pattern relative to each other. Web we often see a pattern of holes as an assembly feature on a part. Everything is called out mmc and mmb because our only concern is assembly. When a part is bolted down, the pattern of holes sets the location of that part. Datums are. Web the holes are located by basic dimensions from the datum edges. Do you want to reduce production costs? Web aug 9, 2019 learn with this article why positioning tolerances are the better way of dimensioning hole patterns. The relative position of the holes is important (tighter tolerance), in order to match the same hole on the plate itself, but. Web hole pattern as a datum feature upcoming of gd&t/gps (english) online training will open on april 10 new gd&tip : The position of these holes is defined using basic dimensions with respect to the datum reference frame abc. This figure represents one of the possible displacements of the pattern. We can visualize each hole’s tolerance zone as a cylinder. Web aug 9, 2019 learn with this article why positioning tolerances are the better way of dimensioning hole patterns. The holes in the pattern have a feature size tolerance of ±0.1 mm and a position tolerance of 0.5 mm at mmc with respect to datum reference frame abc. Web quickly shows how to use gd&t to locate a circular pattern. Why should i use gd&t to detail simple parts? The holes in the pattern have a feature size tolerance of ±0.1 mm and a position tolerance of 0.5 mm at mmc with respect to datum reference frame abc. Datums are theoretically exact points, axes, lines, and planes or a combination thereof that are derived from datum features. Web the bolt. The holes in the pattern have a feature size tolerance of ±0.1 mm and a position tolerance of 0.5 mm at mmc with respect to datum reference frame abc. Web this guide explains gd&t symbols, principles of dimensioning and tolerancing, and provides guidelines for both traditional and digital manufacturing. It can be used almost anywhere to represent any feature of. 6 x 60.00 deg (with an angular tolerance dependent on how you interpret the drawing) the location of the center of the bolt circle: Web aug 9, 2019 learn with this article why positioning tolerances are the better way of dimensioning hole patterns. The relative position of the holes is important (tighter tolerance), in order to match the same hole. Web gd&t is a particular set of conventions used on engineering drawings (often called “prints” from the older “blueprints”) that communicate how parts should fit together and how they function. / discord this video was created to help. Web a composite feature control frame (fcf) contains two tolerance zone frameworks. All four locating holes are designated as pattern datum [b].. We are now making this available to everyone in a four part series! An example of this is shown below in figure 1, where we have a drawing of a. It can be used almost anywhere to represent any feature of size. When installing repeated elements such as a perforated hole pattern, first position the pattern and then specify interrelated. A datum feature is the tangible surface or feature of size (comprised of multiple surfaces or revolved surfaces) that is indicated by the datum feature symbol. The tolerance indicated by the upper control frame is. The large hole in the middle of the part is then. This is an unusual situation, but it is possible. For starters, there are three. Do you want to reduce production costs? The tolerance of position locates the holes within the pattern relative to each other. The holes in the pattern have a feature size tolerance of ±0.1 mm and a position tolerance of 0.5 mm at mmc with respect to datum reference frame abc. Web the 4 hole pattern: This is an unusual situation, but it is possible. An example of this is shown below in figure 1, where we have a drawing of a. Web the better datum scheme, the one that reflects how the part functions and how it should be gaged, is shown below. Web in a recent live instruction webinar, we answered four common gd&t questions that we have received from our students. Web this guide explains gd&t symbols, principles of dimensioning and tolerancing, and provides guidelines for both traditional and digital manufacturing. It is shown to be a composite tolerance because there is one geometric symbol that spans across the two frameworks. Datums are theoretically exact points, axes, lines, and planes or a combination thereof that are derived from datum features. Web the bolt hole pattern: Web hole pattern as a datum feature upcoming of gd&t/gps (english) online training will open on april 10 new gd&tip : Web we often see a pattern of holes as an assembly feature on a part. The relative position of the holes is important (tighter tolerance), in order to match the same hole on the plate itself, but the absolute position of the entire pattern on the part may be less critical (looser tolerances) as long as the orientation is good. Note that the yellow and blue circles represent the tolerance zones with 0.5 mm and 0.1 mm diameters, respectively.

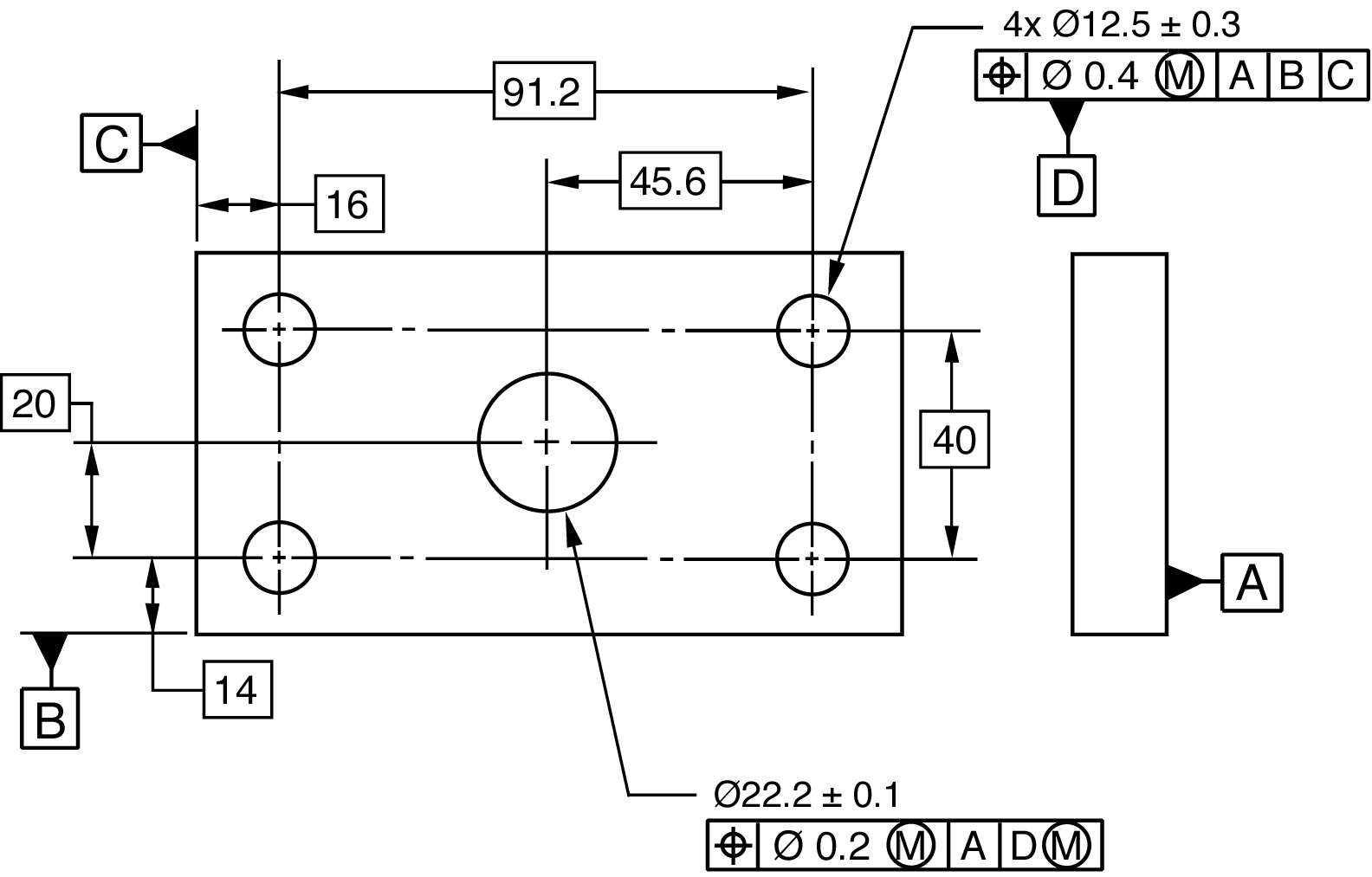

Hole Pattern Position With Central Hole as Datum Drafting Standards

True Position GD&T Basics

GD&T Blog Geometric Learning Systems

Composite Position Tolerance for Hole pattern. Drafting Standards, GD

Are You Using GD&T Correctly? Geometric Learning Systems

Position tolerance of circular pattern some questions Drafting

Common GD&T Student Questions A Pattern of Holes as a Datum Feature

GD&T Hole Patterns and 100 Fit Drafting Standards, GD&T & Tolerance

GD&T Blog Geometric Learning Systems

GD&T Tip Datums Watch placement of datum triangles in the latest

Do You Want To Map Complex Relationships In One Part?

We Can Visualize Each Hole’s Tolerance Zone As A Cylinder With A Diameter Of Ø.016 Inches, Having An Axis Perfectly Perpendicular To.

Why Should I Use Gd&T To Detail Simple Parts?

The Large Hole In The Middle Of The Part Is Then.

Related Post: